Powder coating is just like liquid paint, only better.

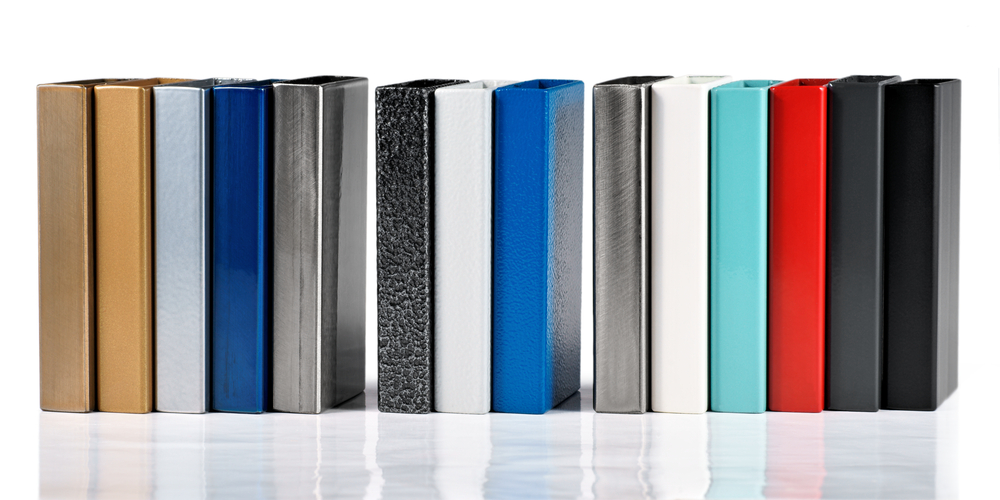

While powder coating is more economical and environmentally-friendly than traditional liquid paint, it has the same range of colors and finishes as its rival.

Additionally, depending on what’s being powder-coated, you can choose a finish that will protect your objects over a long time. Powder coating finishes includes anti-graffiti glosses, that prevent inks and other paints from sticking to it, and heat resistant styles that protect objects frequently exposed to high temperatures. Powder coating are prized for their durability over the long term, in terms of retaining their original color tones and resisting nicks, scratches and other abrasions.

What type of powder coating should I choose?

Powder coatings are available in four basic types, each offering different performance attributes.

- Epoxy for the best corrosion protection.

- Hybrid(s) typically offer the best chemical and solvent resistance.

- Polyurethane offers flexibility and hardness suited for moving parts.

- Polyester for the highest exterior stability and performance.

The type of powder coating finish that’s best for any project varies on the object and materials chosen.

Learn more about the wide range of textures and colors of powder coating we have available.