Powder coating is engineered to have several advantages over traditional liquid paint. Here are just a few key benefits of using powder coating over liquid paint.

Reduce VOC Emissions

Powder coating eliminates air and water pollutants that are produced by solvent paint, helping reduce emissions. They don’t require solvents or thinners for mixing or for clean-up and there are no environmental stressors during application making a better solution for metal coatings for the environment.

Better Efficiency

Powder coating is more efficient and economical when compared to liquid paint because in some instances powder coating overspray can be reclaimed and reused while liquid paint overspray is lost. Unlike liquid paint, which can be spilled even in the best conditions, virtually the entirety of a powder coating product can be recovered and used. Some powder coating systems can be run with minimal manpower and upkeep. Air inside the powder coating systems is easily filtered before being returned back into the coating plants.

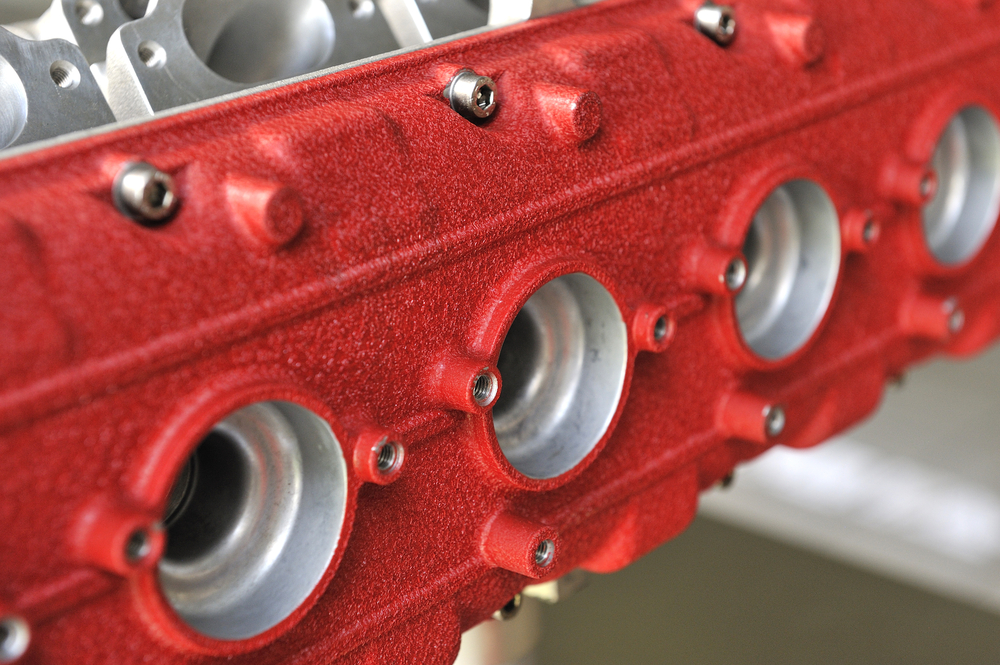

Produces Better Coatings

Powder coating goes on evenly with fewer chances for sagging or drips. Even oddly-shaped objects or details like holes and edges are evenly covered with the desired thickness of powder coating. Powder coating has been shown to better resist corrosion when compared to liquid paint undergoing the same conditions.

More Economical

Powder coating systems are more cost competitive than liquid paints, costing less for a variety of reasons including that they are 100% solids and powder recovery allows for nearly 100% material utilization. Powder coated products can withstand years of service with minimal wear and less maintenance than standard paint.

Overall, powder coating is the better option.